Yarn twisting

Yarn dyed fabric needs treatment of yarns before dyeing. Yarns are twisted before dyeing for firming and avoiding nap. In case that the yarns are not twisted enough, the fabric is made with nap. In case the yarns are twisted too much, the fabric becomes firm.

The yarns for Loisir collection are twisted 650 times for warp and 300 times for woof, which is the best balance of yarn twisting.

Deying

Deyings are done as the same time as the number of colors that you see on the fabric. As the dyed up yarns weight is twice of their weight because of the water, they are drained and dried. After dried, the yarns loose their proper moisture as Cupro. So they must moisten to regain it.

The standard moisture level of Curpo is 11% comparing to its own weight which is the same ratio as silk. The yarns need 4 days for drying, 3 days for moisten.

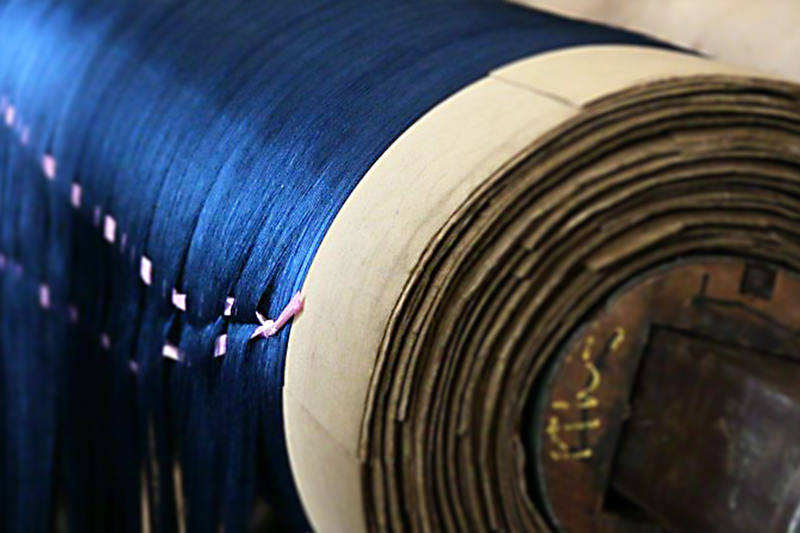

Yarns for warp

The yarns with optimal moisture are rolled according to the fabric pattern for placing on loom.

Weaving

The yarns which are rolled according to the pattern are placed on loom attentively by hand. Then the woof is set and weaving starts. One loom can weave 50 meters per day......The fabric needs great care and time.

Finishing

Curpo is delicate and luxurious fabric which needs 5 days with many treating process. Once woven up, the fabric is inspected visually by 2 persons. Only the fabric passed this inspection can be Loisir Collection.